Knowles Blog

Can You Hear Me Now? Ansys Turns up the Volume on Hearing Device Designs

October 11, 2022 - Ansys Blog

Years ago, hearing aids consisted of a belt pack and a wire that ran up from the waist to the user’s ear. A lot has changed since then, as hearing devices have become much more sophisticated. Now, the hearing health market is all about higher efficiency devices that are also more compact in size. If you can make a hearing aid transducer smaller then you can enable people with hearing loss to wear devices that are more comfortable and discreet. The Knowles product team relies on Ansys to achieve these goals.

Hearing aids evolved and shifted from belt pack to the ear in large part due to subminiature balanced armature (BA) driver technology. Today, most of the world's hearing aids use balanced armature receivers, and Knowles is a leading supplier. If you’re not familiar with the technology, a balanced armature is a special class of speaker used in hearing aids. You’ll also find them in premium audio earphones and Bluetooth true wireless stereo (TWS) devices. Musicians often use custom earphones with multiple balanced armature speakers so they can hear their band playing with better fidelity while protecting their hearing.

Avoiding the “Shock” of Mechanical Failure with Ansys Mechanical

Hearing aids and earbuds on this small of a scale can sometimes pop out of the ear during activities, or users can fumble and drop them. When you’re dropping an earbud from a couple of meters onto a hard surface, the extreme acceleration due to gravity on a hearing aid receiver comes into play. What the device is experiencing is referred to as mechanical shock, or a sudden impact that transmits energy through the device in less than a millisecond, potentially causing failure to the balanced armature inside.

For Knowles and their customers, a hearing aid’s durability is an important part of a balanced armature’s overall performance. To make the design of the BA as robust as possible requires a lot of testing. The traditional approach to evaluating mechanical shock involves mounting the balanced armature in something that simulates a hearing device, then dropping it repeatedly.

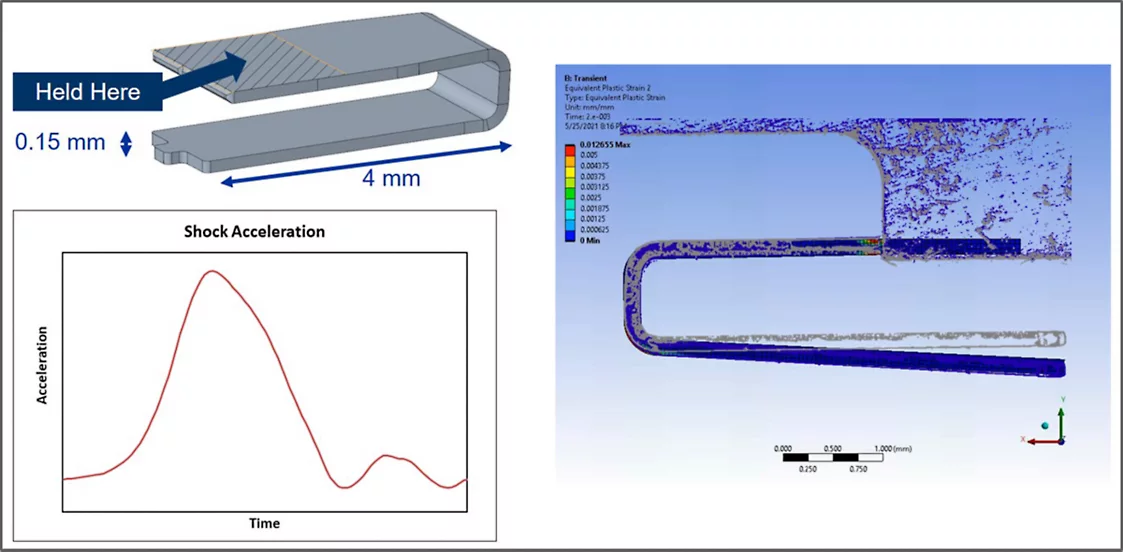

Knowles looked to Ansys Mechanical simulation software to simulate the impact of mechanical shock on BAs in a variety of known environments at both the product and system levels. It also helped Knowles find ways to improve the shock reliability of their products in those environments, and to characterize component material in both static and dynamic situations.

“Ansys provided a lot of support and was able to connect us with the right people to determine all of the time steps and settings, including the contact settings and mesh settings within Ansys Workbench needed for simulation,” says Chris Monti, manager of new technology development at Knowles. “For our purposes, we believe that Ansys has the strongest portfolio of products for simulating shock damage — particularly since our analysis involves material damage to a metal due to plastic deformation.”

Capturing Material Bending Moments of Tiny Parts

One of the challenges that Knowles faced in simulating shock was determining the correct material properties to use for their magnetic metal alloys. To do this, Knowles used a variety of simulations including modal, static, and transient simulations. These simulations were then compared to lab testing to fit an appropriate material model.

In one example, Knowles developed their own three-point bending equipment to test the tiny reeds that are used in receivers. One of the most easily damaged components of any BA is the reed, which is made from a specialty magnetic alloy. The reed moves up and down in the BA to push on a diaphragm that produces the sound that comes from these miniature speakers.

An example Knowles reed (top left) and an example shock acceleration environment (bottom left). The image on the right shows an Ansys simulation matching with the measured deformed shape of the reed; the undamaged reed is shown in gray for reference.

Engineering a shock isolation system within a customer’s device also improves shock performance at the system level, and helps Knowles protect their own components in the process. Recently, the Knowles team was called upon to improve the system-level shock performance of their BA within in a customer’s design. Knowles decided to design their own isolation system utilizing Ansys simulation tools to quickly create new 3D printed suspensions. In this case, traditional static measurement techniques were not necessarily effective for modeling the stiffness of rubbers. Instead, the team at Knowles measured the material properties at high frequency on a shaker table.

Knowles was able to improve the shock reliability of their BAs to survive more drops (blue curve to green curve). By improving the isolation system the R&D team was able to provide further improvement that resulted in 100% survival (red curve).

“With this approach, we could characterize the behavior of the material at a frequency that's much more relevant to the shock events,” says Monti. “We then used a harmonic simulation within Mechanical to confirm the behavior matched what we were seeing in the lab, and to fine-tune the stiffness and the damping properties of the material.”

Ansys Maxwell Attracts Confident Magnet Analysis

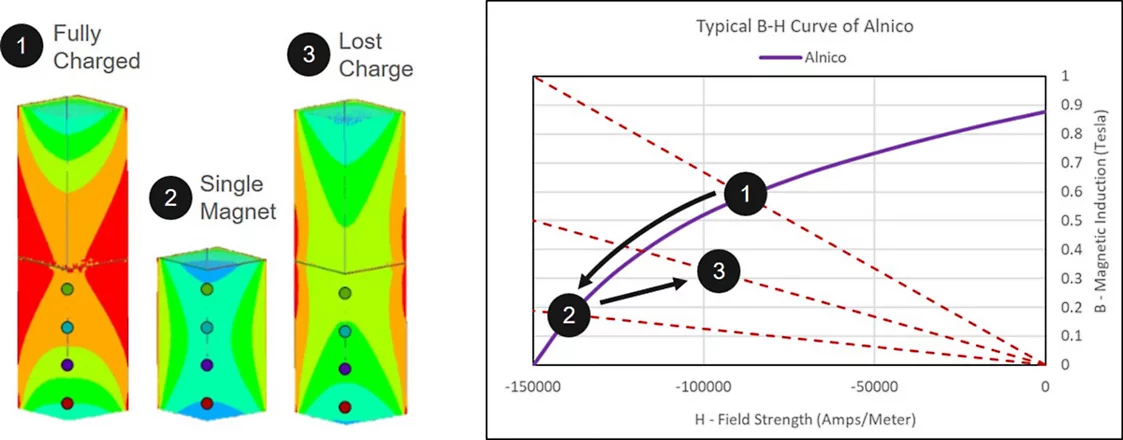

Knowles’ use of simulation is not limited to Ansys Mechanical. In a recent case study, they used Ansys Maxwell low-frequency electromagnetic field simulation software to analyze a magnetic material composed of aluminum, nickel, and cobalt called alnico. Unlike neodymium magnets — the strong, silvery-colored magnets familiar to most grade-school scientists — alnico magnets operate very differently in various environments. Alnico is the preferred magnetic material for use in balanced armature receivers.

“Maxwell was the only tool we found that can model the behavior of alnico as operates in its fully charged and partially charged states,” says Monti. “Thanks to Maxwell we are able to see how different parts of the magnets respond to different situations.”

Knowles was able to model the demagnetization of alnico that occurs as a tall magnet (step 1) is separated into two shorter magnets (step 2). The material then behaves linearly (step 3).

The team leveraged Maxwell to simulate the behaviors of the individual magnets that are in their balanced armatures, including the demagnetization behavior of these magnets in real-world conditions. Thanks to Maxwell's stability and meshing capabilities, Knowles can confidently run system-level structures analysis that leads to better hearing device designs.

“Maxwell is the tool we trust to always give the right answer to our biggest magnetic simulation challenges,” says Monti. “We believe its user-friendly meshing provides a stable simulation environment that can accommodate geometry that is difficult for other simulation tools to model.”

Ansys Tools Break Down Barriers to Innovation

Monti was quick to mention that due to the nature of the innovative environment they play in, his team doesn’t always have well-established workflows for the simulations they perform using Ansys software. Every day brings something new, presenting new design challenges that require new solutions. The Ansys portfolio offers the flexibility needed to respond to this ever-shifting landscape and take their technology in new directions.

“Most of the simulation work my team does is on newer investigations, and Ansys tools play an important role in meeting our customer’s requirements,” says Monti. “Using simulation we can significantly cut down our design cycles and time to market.”

Interested in hearing more about Knowles’ use of simulation to improve hearing health? Be sure to sign up for Ansys’ Level Up 3.0 engineering simulation conference and catch Chris Monti’s in-depth presentation.